Molten Miracles

Picture blazing hot furnaces, heavy, hard-to-operate machinery and giant cauldrons the size of small bathtubs filled with molten glass so hot it could literally melt your face off.

Helena Pátková, Preciosa's glasworks director

Glass production on an industrial scale is no joke. It is a serious, highly skilled practice that requires precise coordination of many simultaneous processes and can be dangerous if not approached correctly. But if you think this sounds like a man’s job, think again. Let us introduce you to Helena Pátková. She oversees Preciosa’s principal glassworks, comprising a team of ninetyone people whose singular mission is to mix, melt and pre-shape as many colorful crystals as they can. Located along the Prysk stream in an idyllic North Bohemian village, this facility is where most Preciosa crystals begin their lifecycle, and where we met with Ms. Pátková to learn more about what goes into the production of two hundred tons of molten glass every year.

Preciosa: Helena, you have been with Preciosa for more than twenty years, and now oversee the entire glassworks production at Prysk. Can you tell us a little bit about how you ended up in this role?

HP: I began working for Preciosa right after I graduated from school. Throughout my time here, I have held various roles in both quality control and glassmaking. I am honestly fascinated by glass – its versatility, its tradition here in Bohemia, the melting process, all of it. So, when I was offered a directorial position at our Prysk plant, I jumped at the opportunity with the goal of making positive changes and taking a more innovative approach to our glassmaking process.

Preciosa: So, how does it all begin? What is the first step in the production process of a crystal?

HP: First, you need to create the mixture, which comprises mostly of sand and specific coloring agents. This is a highly intricate process, and it varies not only according to color but also according to size of the finished crystals. We work with more than fifty different base mixtures, each with its own distinct properties and requirements. While every step of the process is important, this one is probably the most crucial because if the mixture is not exactly right, the whole glass batch becomes unusable and has to be re-melted down.

Preciosa: Is there a secret to producing high-quality melts?

HP: It is a combination of expert knowledge, effective machinery and top-quality raw materials, the most important of which is our sand. This region became famous for glass and crystal production largely because of its abundance of pure, high-quality sand, which gives our glass its signature shine. Preciosa sources almost everything locally, which is “half the battle” so to speak – if the ingredients are not high quality, you cannot expect a high-quality melt, so we are fortunate to be working with only the best materials. The rest is about timing and precision.

A secret to producing high-quality melts is a combination of expert knowledge, effective machinery and top-quality raw materials.

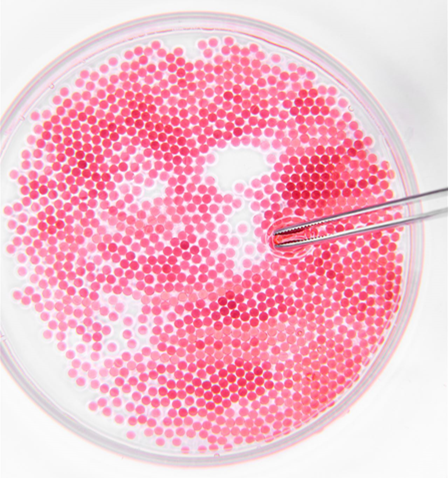

Our latest color innovation Rose Peach blanks after striking.

Preciosa: You mentioned that machinery plays a key role in this process. How important are the machines, and how important are the people operating them? Is there anything that can only be done by hand?

HP: Modern, industrial-scale manufacturing demands the use of machinery; however, human expertise and Preciosa’s collective savoir faire is absolutely essential. For instance, the process of testing each melt is entirely done by a person who manually extracts, presses and assesses the molten glass. Similarly, our quality control measures are conducted entirely by people. The process is truly a blend of technology and human input, and of tradition and innovation. Some of the machines in operation today are decades-old yet are simply unmatched in efficiency. Plus, many of these machines are extremely specific and require the detailed attention of someone who is trained to operate them. I believe this integrated system is the way forward and will continue to be crucial to Preciosa’s success.

Preciosa: What expertise do you bring to this role?

HP: My previous work, especially in the quality department, has proven invaluable. I am good at troubleshooting, and I have an in-depth understanding of the intricacies of the process that take years to absorb. These are not things you can pick up in a week-long on-boarding. I am also fortunate to have an exceptional team, whom I view more as collaborators. I am not an expert in all technological aspects of the glass melting process, but the people I work with certainly are. This is something I highly value – we have a strong culture of collaboration, not just here in Prysk, but across the whole of Preciosa, which provides us with opportunities to grow and to innovate.

Preciosa: What professional accomplishments are you most proud of ?

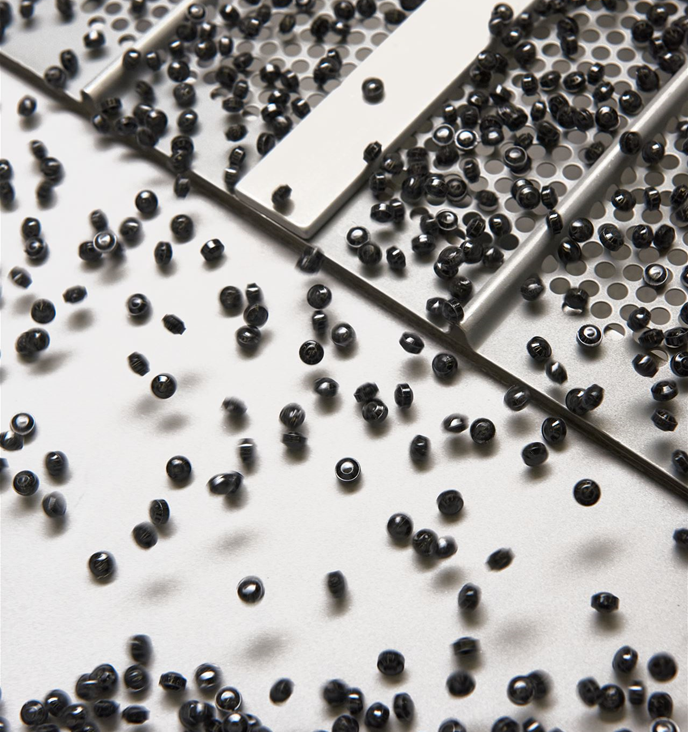

HP: We have been able to master several complex glass shades that are entirely unique to Preciosa, such as Erinite (2018) and color-changing Mesmera (2022), which makes me extremely proud. I have also overseen the implementation of some new processes that streamline transformation of the molten glass into a preform – tiny, pre-shaped balls that are cut and polished later in the production process – which has led to more efficient, sustainable production.

Preciosa: Can you share some of the most challenging tasks you have faced recently?

HP: The past few years have been rife with challenges, from navigating the impacts of the pandemic to adapting to the energy crisis caused by the situation in Ukraine. These challenges forced a shift in our energy sources, from gas to electricity, though for certain glass colors, we still rely on gas furnaces. In terms of production, our new color Rose Peach proved to be one of the most challenging shades we have ever developed, but overcoming these challenges is what drives us forward, so this one was welcome.

Preciosa: And – we have to ask – what is your favorite Preciosa color?

HP: Erinite or Limecicle! I love our greens.

Related articles

Preciosa's Crystal Innovations SS 2025

Open a portal to a realm of sparkle and whimsy with our excting novelties.

Beyond Business

Putting people first: Our approach to employee well-being

The secret agents of sparkle

Glass recipes are complex, not to mention highly protected secrets.

Laboratory Testing

From extreme heat to high-speed spin cycles, Preciosa crystals undergo some seriously demanding stress tests.