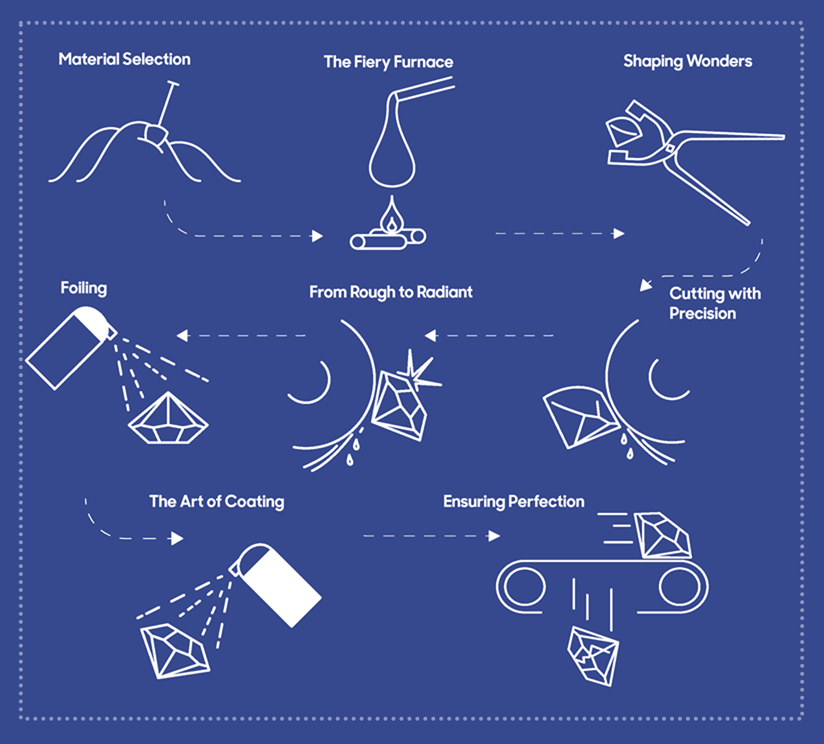

Crafting Brilliance

Reflected in every Preciosa crystal is the incredible skill, dedication, and technology it takes to bring each one to life.

A perfect blend of centuries-old savoir-faire, state-of-the-art technology, and more than 100 unique professions coalesce to create a crystal components portfolio that sets the standard for sparkle throughout the world.

Material Selection:

The first step in the lifecycle of a crystal is the meticulous task of choosing the right materials. The chosen blend of silica-rich sand, soda, potash, and coloring and stabilizing agents achieves the signature brilliance the world has come to associate with highest-quality Preciosa crystals. This is a job not only for purchasing specialists, but also for chemists, laboratory technicians and of course batch mixers – the people who physically prepare the materials for the next step.

The Fiery Furnace:

Imagine a roaring furnace at a blistering 1,400°C within which the basic ingredients transform into molten magic – crystal glass. This stage is a testament to the balance between age-old alchemy and modern precision glass melters, furnace operators and process technicians.

Shaping Wonders:

Here, the molten glass is molded into a variety of rough forms that will eventually become one of Preciosa’s many precision-cut crystal shapes. This art requires an understanding of not just the machines but also the different ways each glass mixture behaves. Preciosa’s many glass shaping specialists and mold technicians are not merely workers, but true glass artisans.

Cutting with Precision:

Did you know Preciosa employs more than 160 grinding machine operators? Their task is to wield the machinery that transforms rough glass into perfectly cut marvels. Their number may seem excessive, but precision is in Preciosa’s DNA and this stage leaves little room for error.

From Rough to Radiant:

After cutting, Preciosa’s production planners send the stones to be polished. It is in this stage that the crystal begins to reveal its true potential, dancing with light and capturing imagination. Preciosa’s polishing technicians make sure of that!

Foiling:

The application of a reflective coating on the underside of the crystal is a job for the foiling specialists. This extremely durable layer increases the stone’s brilliance by reflecting light back through the crystal. To enable such durability, Preciosa takes the extra step by employing its own nanotechnology chemists.

The Art of Coating:

While not all crystals undergo this step, the ones that do are transformed. Crystals coated in iridescent Aurora Borealis, for instance, undergo a special process that creates an enchanting rainbow effect. Preciosa’s team of coating specialists turn colored and Crystal stones into artifacts of wonder.

Ensuring Perfection:

Quality is not just a buzzword for Preciosa; it is a way of life. A vast team of quality controllers together with a variety of machines ensure that every crystal that leaves our facility is nothing short of perfection.

In our world of fast fashion and instant gratification, our crystals remind us of the beauty of patience, skill, and quality.

The Final Touch

As the crystals prepare for their journey into the world, a dedicated team packages them with the same care and attention to detail the crystals receive from the beginning of the process. And these are only the positions that require interaction with the crystals. Supporting each of these men and women is a robust network of professionals, from maintenance teams ensuring the machinery runs like clockwork, to HR professionals and even cooks who fuel the workforce’s daily grind.

It is astounding to realize that a single crystal is the product of such a vast and varied community. Preciosa crystals are not just decoration; they represent tradition, innovation, and an unwavering commitment to excellence. Behind every shimmer, reflected in every shine is an entire ecosystem of dedicated professionals and state-of-the-art technology working together to craft unsurpassed brilliance every single day.

Related articles

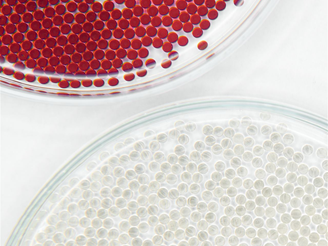

Sorting and Recycling of Glass

Recyled materials account for 5-20% of the total volume of every new batch of glass Preciosa makes.

The Path to Cleaner Crystal

Emissions Reduction

The Magic of Striking

Turning Gold and Silver into the new crystal color Rose Peach.

Molten Miracles

Interview with Helena Pátková, Glassworks Director